Penpet Petroenergy Corp : The New Way to

1. TITANIUM DIOXIDE

Titanium dioxide, a versatile and essential pigment in the paint industry, enhances paint's opacity and brightness. As a white pigment, it reflects light, providing superior coverage and vibrant colors. Its UV-resistant properties prevent paint fading, ensuring long-lasting color vibrancy. Additionally, titanium dioxide enhances paint's durability and weather resistance, making it ideal for both indoor and outdoor applications. Its non-toxic nature and environmental compliance add to its appeal. In summary, titanium dioxide is an indispensable component that elevates the quality and performance of paints, contributing to their aesthetic appeal and protective qualities.

2. RDR POWDER

RDR (Redispersible Polymer Powder) is a crucial additive in the paint industry. This white, free-flowing powder enhances paint performance by improving adhesion, durability, and flexibility. When mixed with paint formulations, it creates a cohesive, long-lasting film that resists cracking and ensures a smooth, even finish. RDR powder also helps control the paint's consistency, reducing sagging and improving workability. It plays a pivotal role in exterior paints, interior paints, and even decorative finishes, making them more resilient against weathering and wear. In essence, RDR powder is the unsung hero behind high-quality, durable paints used in various applications.

3. ZIRCOM

Zirconium silicate, commonly known as zircon, is a vital component in the paint industry. Its fine particle size and exceptional whiteness make it an ideal opacifying agent in paint formulations. Zircon functions as an opacifier, enhancing the hiding power of paints by scattering light and concealing the substrate. This quality is especially valuable in producing high-quality, opaque, and vibrant coatings, including primers, exterior paints, and enamels. Zircon also improves the durability and resistance of paint films to environmental factors. In essence, zircon's usage in the paint industry results in more effective and visually appealing coatings.

4. MELAMINE

Melamine is utilized in the paint industry as a cross-linking agent and resin modifier. Its high reactivity and excellent adhesion properties enhance the durability and gloss of coatings. Melamine-based resins are commonly employed in wood and metal coatings, offering exceptional hardness, chemical resistance, and improved scratch resistance. Furthermore, melamine's low formaldehyde emissions make it an eco-friendly choice for low-VOC (volatile organic compound) paints. In the paint industry, melamine plays a crucial role in formulating coatings that are not only aesthetically pleasing but also highly durable and environmentally responsible.

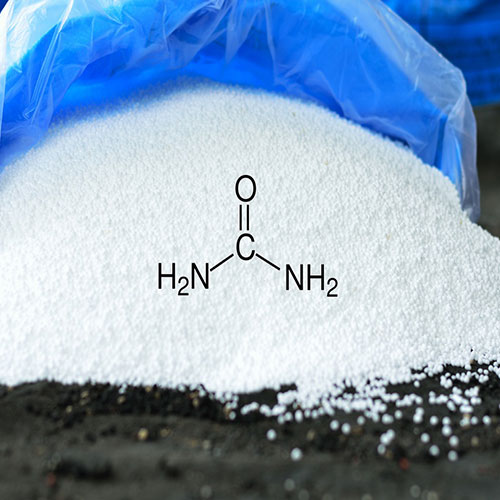

5. UREA

Urea, in the paint industry, serves as a crucial component in water-based paints and coatings. Its primary role is to enhance the paint's adhesion, providing a smooth and even surface. Urea acts as a dispersing agent, preventing pigment clumping and ensuring color uniformity. Additionally, it assists in controlling the viscosity of paint, facilitating application. This compound is also utilized as an anti-skinning agent, preventing the formation of a skin on the paint's surface during storage. Urea's eco-friendliness, low toxicity, and compatibility with other paint additives make it an essential ingredient for the formulation of high-quality, environmentally conscious paints.

6. HMEC

Rheology modifiers are essential in the paint industry, influencing the paint's flow and texture. These additives control viscosity, preventing splattering during application and ensuring uniform coverage. They enhance paint's stability, enabling it to endure storage and transportation without settling or separating. Additionally, rheology modifiers aid in achieving the desired finish, whether smooth or textured. In essence, these agents are the silent heroes that make paints easy to apply, visually appealing, and long-lasting, greatly contributing to a superior painting experience and the quality of the end product.